Aluminum Melting Machine - Manufacturers, Suppliers, Factory from China

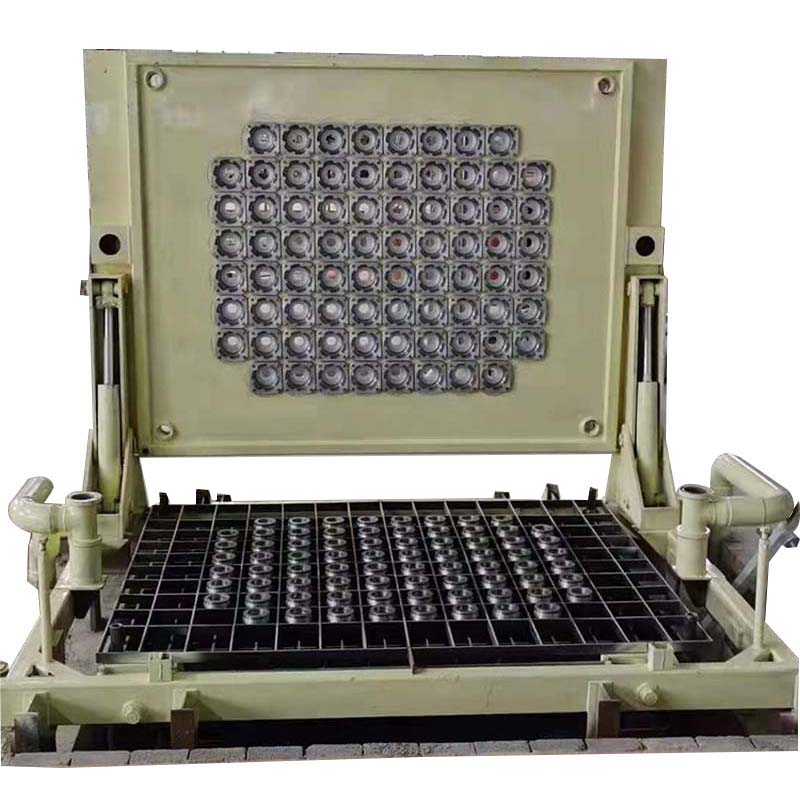

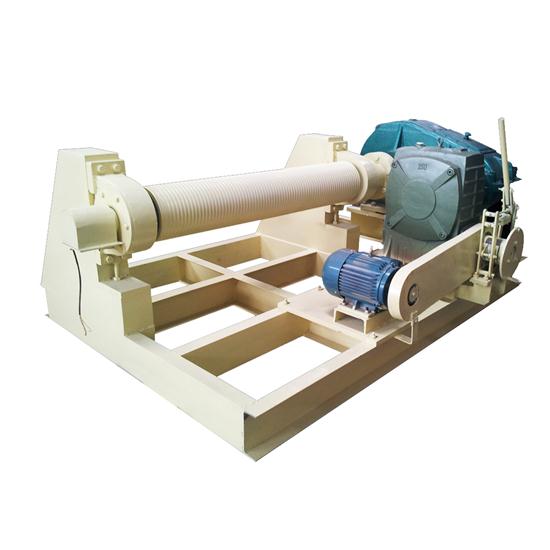

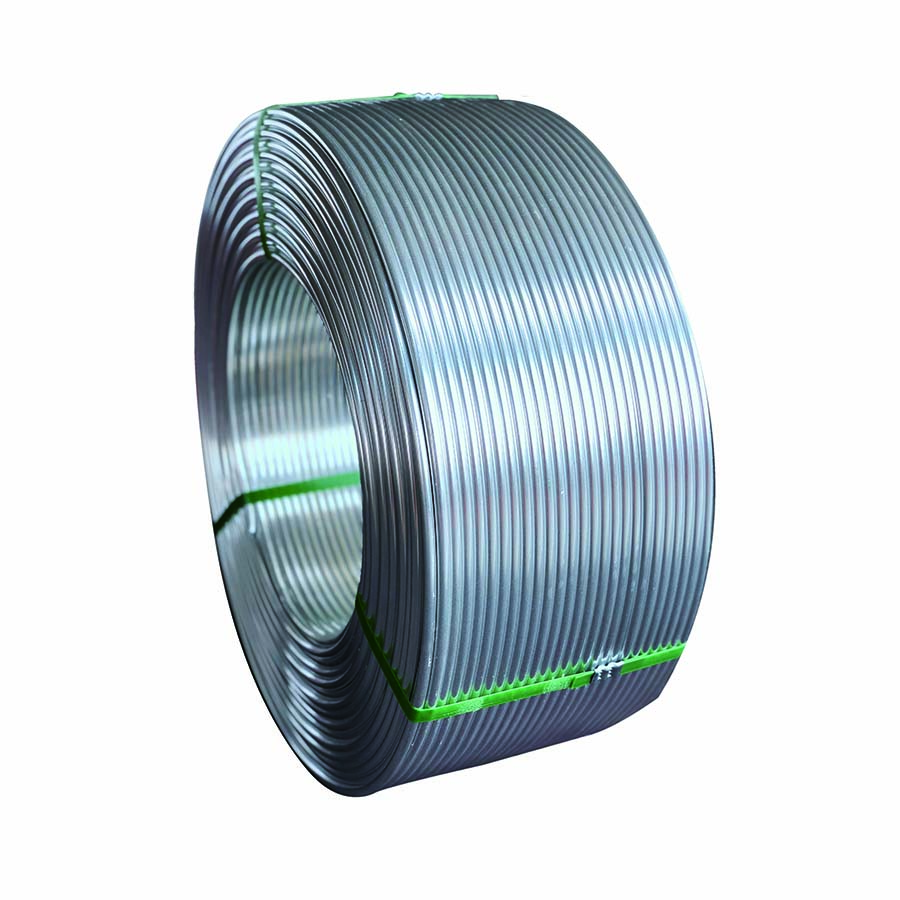

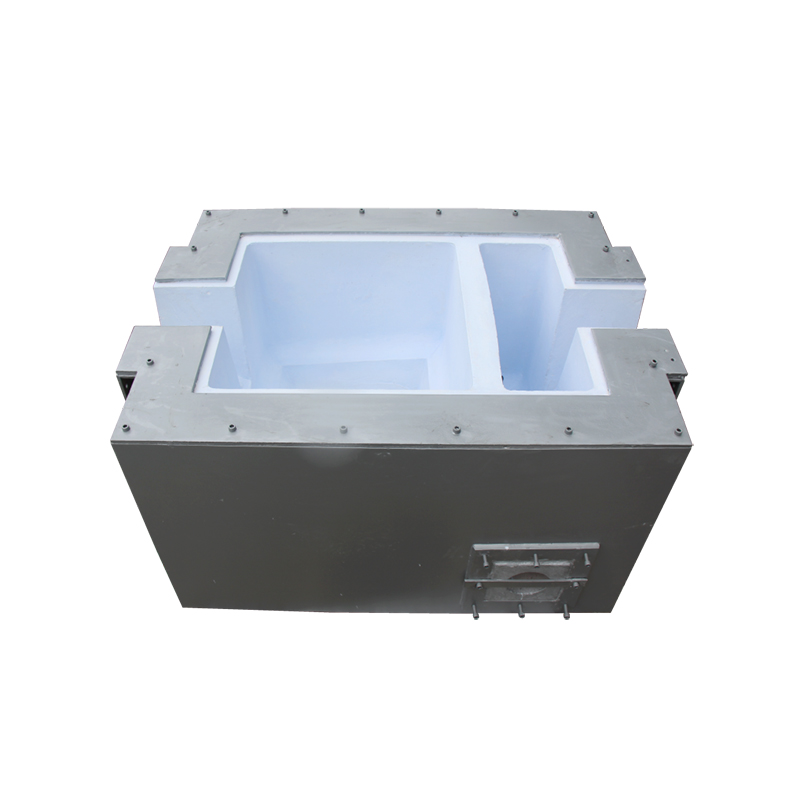

Foshan Zhelu started in 1999 and has been deeply serving in the aluminum industry for more than 20 years in Foshan, where has many aluminum brands such as JMA, Xingfa, Flenlu,called `aluminum city` in China,. Our office, located in the prosperous business district: Nanhai Financial High-tech Zone, provides an elegant and comfortable environment for working, living and entertainment. Adhering to the concept of sincere treatment, excellence, we have been continuously contributing to aluminum plants around the world. Aluminum Melting Machine, Alodine Aluminium Treatment, Vesuvius Canada, Aluminum Casthouse,Extruded Aluminum Bars. Aluminum casting process: The recycled aluminum scrap is to be heated and melted in an aluminum melting furnace,add with pure aluminum ingot, with refining flux and dross flux, the impurities will be removed, Then silicon and magnesium will be put into molten aluminum ,After flowing into launder and filter box,the molten aluminum finally reach the ingot casting line, with stacking robot, aluminum ingot will be stacked and packaging. While aluminium billet is another casting equipment, molten aluminum flows into Hot top casting plate, after cooling and Lifting and lowering of pallets, the billet will be made under the plate, then aluminum billet is hoisted out by the crane and enters the homogenization furnace, finally cut by saw. The product will supply to all over the world, such as Europe, America, Australia,Algeria, Surabaya,Anguilla, Germany.Under the action of pressure, the heated aluminum rod is divided into several metal flows, enters the welding chamber through the shunt hole, collects in the welding chamber, and is welded again in the environment of high temperature, high pressure and high vacuum, and finally flows out through the gap between the mold core and the die hole, so as to form a pipe or hollow aluminum profile that meets the size and performance requirements, as an aluminum door and window profile or industrial aluminum profile. If bending is required, a bending tool is added to the rear device.

Related Products