Aluminum has become a widely used material in various industries due to its high strength and excellent corrosion resistance. However, aluminum’s natural properties have certain limitations, particularly in terms of surface quality. To overcome these limitations, grain refinement of aluminum and aluminum alloys is crucial.

Grain refinement is a process that reducing the size of the grains in a material’s microstructure, making it more uniform and dense. This process is essential to improve the strength, plasticity and overall mechanical properties of aluminum materials or castings. The surface quality of the profiles is also improved, resulting in a uniform, bright appearance.

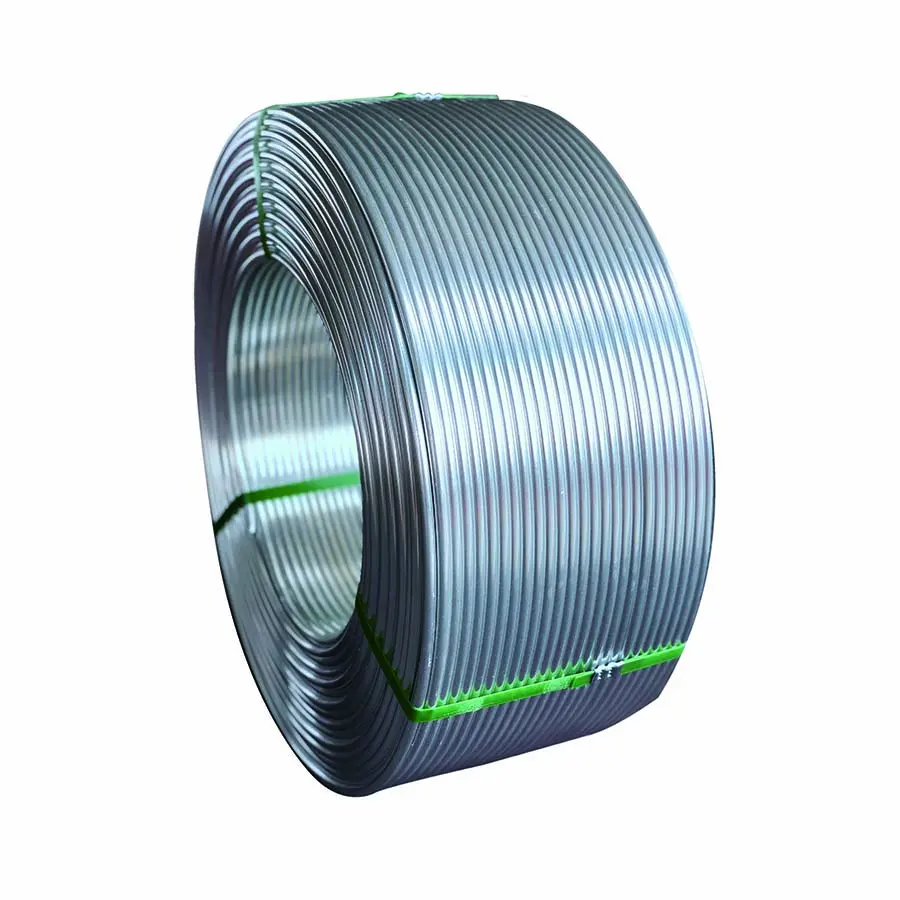

To achieve this grain refinement, the most commonly used on the market is the Al-Ti-B boron wire additive. The wire additive is 9.5 mm in diameter, weighs approximately 100 kg (170 kg) per roll, and is composed of 5% titanium (T) and 1% boron (B). It is designed to meet the grain refinement needs of aluminum and aluminum alloys.

Al-Ti-B boron wire Additive offers numerous benefits, making it an excellent choice for any refining process. First, it significantly improves the properties of aluminum materials or castings. The material’s strength and plasticity are enhanced, making it suitable for applications requiring high mechanical properties.

Additionally, this wire additive reduces scrap rates, resulting in cost savings and increased productivity. By improving surface quality, ensuring profiles have a uniform, bright appearance and adding aesthetic value to the final product.

A significant advantage of Al-Ti-B Boron wire additive is its the way of use.It was used outside the furnace, when the aluminum water is released, directly insert the aluminum titanium boron wire into the ceramic launder through the feeder to melt and refine, and ensure that the aluminum titanium boron wire and the aluminum liquid are in contact for more than 1 minute (preferably 2- 10 minutes). The dosage is generally 0.8-1.3kg/ton of aluminum (the diameter of the aluminum-titanium-boron wire is 9.5mm, and the weight is 0.192kg/m). Furthermore, the additive ensures that titanium boron is not lost during the refining process.

The versatility of this wire additive makes it suitable for a wide range of applications. Widely used in aluminum castings, aluminum profiles, aluminum cables, aluminum foil and other industries.

Post time: Oct-20-2023