Nickel additive for aluminum alloy casting

Instructions for use:

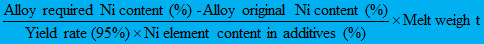

1. The following formula:

Note: Due to the difference in metallurgical conditions between users and furnaces, the actual yield and actual addition amount should be calculated and determined based on the test data before the furnace.

2. Add method:

Adding method: After the charge is melted, stir evenly, take a sample and analyze to calculate the amount of nickel agent added. When the temperature of the melt is reached, remove the dross on the surface of the melt, and then disperse the product into various parts of the melt pool.

Stand still for 20-30 minutes, fully stir for 5 minutes, and then stand still for 10-20 minutes until the melting is complete, take samples for analysis, and transfer to the next process if the ingredients are qualified.

3. Add temperature: >730℃

4.Package storage:

This product is dark gray round cake-shaped solid, the inner packaging is moisture-proof paper and plastic bag packaging, 250g/pcs, 1kg/bag, 20kg/box. Store in a ventilated and dry place, away from moisture, because the metal powder contained in the additive is highly active and easy to oxidize, the flux contained in the additive susceptible to moisture, the surface of the additive is oxidized after damp, and in severe cases, there will be pulverization, thus affect the actual yield, or even fail.

5.The shelf life is 8 months, ready to use out of the box.