The application of the crystallizer in hot top casting has brought huge changes to the aluminum billet casting process. It is an important component to ensure that aluminum liquid solidifies into aluminum rods.

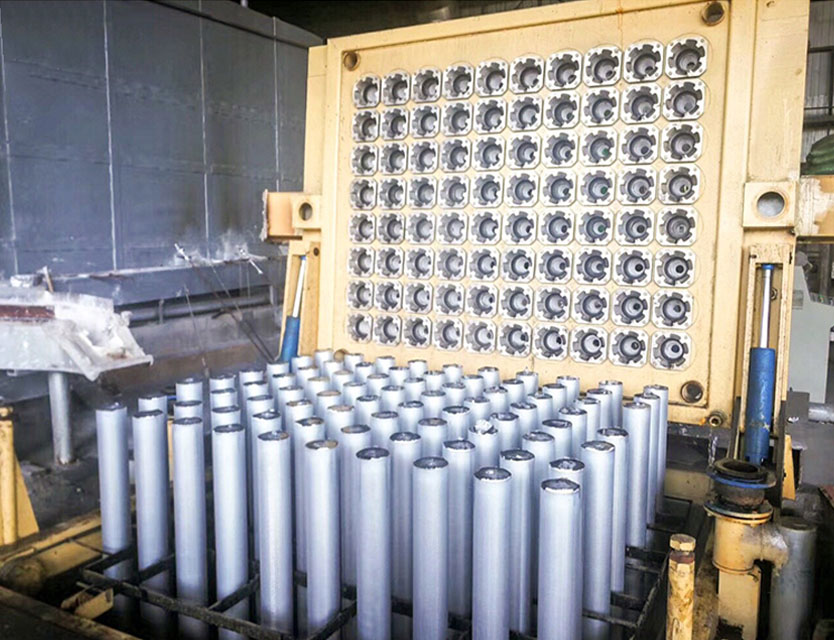

The crystalliser is a key component of the casting machine system and needs to be replaced frequently in the short and medium term. Therefore, the requirements for rational design and process precision are very high. As a leading supplier, Zhelu’s crystalliser are well-designed, precise, high-performance and easy to dismantle and clean, and can be customised to meet customers’ requirements, including hot-top round bar crystalliser, horizontal round bar crystalliiser, horizontal square bar crystalliser, slab billet crystalliser and rectangular crystalliser, etc. These features enable them to be adapted to various casting environments and to meet customers’ different needs. These features enable them to be adapted to various casting environments to meet the different needs of customers.

One of the greatest benefits of using a crystalliser is the ability to ensure uniform cooling of the cast billet. During the casting process, a controlled cooling rate must be achieved to prevent any structural defects or inconsistencies in the cast billet. A uniform cooling process can be achieved through the innovative design of the crystalliser. This not only improves the quality of the aluminium billet, but also the efficiency of the entire casting process.

Easy mould release is another advantage of zhelu crystallizer. The structure of the crystallizer has been specially designed to facilitate the production of aluminium bars with good surface quality during the casting process. This feature considerably saves time and effort and allows for working efficiency. The simplicity of the crystalliser construction, consisting of graphite rings, high purity graphite and red copper material, increases efficiency and effectiveness. Complexity is reduced by minimising the number of components and keeping the design simple. zhelu’s crystallizers are simple in construction, easy to install, strong, rigid and impact resistant. Their simplicity is also demonstrated by their ease of disassembly and cleaning for maintenance and servicing.

Crystallizers are also useful in determining the shrinkage of cast billets. different type and sizes alloy has different shrinkage rate, and the crystalliser minimises any shrinkage or distortion that may occur during solidification. This helps to produce a high quality product that meets the requirements.

Another piece of equipment that is closely related to the hot top casting system is the steel wire rope casting machine, because the liquid aluminium is coalesced from the liquid state into aluminium billets via the crystallizer and the crystallizer outlet is a water curtain, which needs to be pulled down by the steel wire rope casting machine to ensure that the aluminium billets are formed and the right height.

In short, the crystallizer occupies a high position in the application of aluminium billet casting system. ZELU crystallerizer are characterised by reasonable design, precise structure, excellent performance, easy disassembly, assembly and cleaning, and long service life. Becoming the favoured products in major markets, they are able to adapt to a variety of different casting environments and meet customer requirements. Their features of even cooling, easy mould release, simple structure and determination of shrinkage rate help the casting process to achieve full success. ZELU’s crystallizers adopt user-friendly customized requirements, the latest design and manufacturing technology, paving the way to win overseas markets and improve the efficiency and quality of aluminium billets casting.

Post time: Sep-14-2023