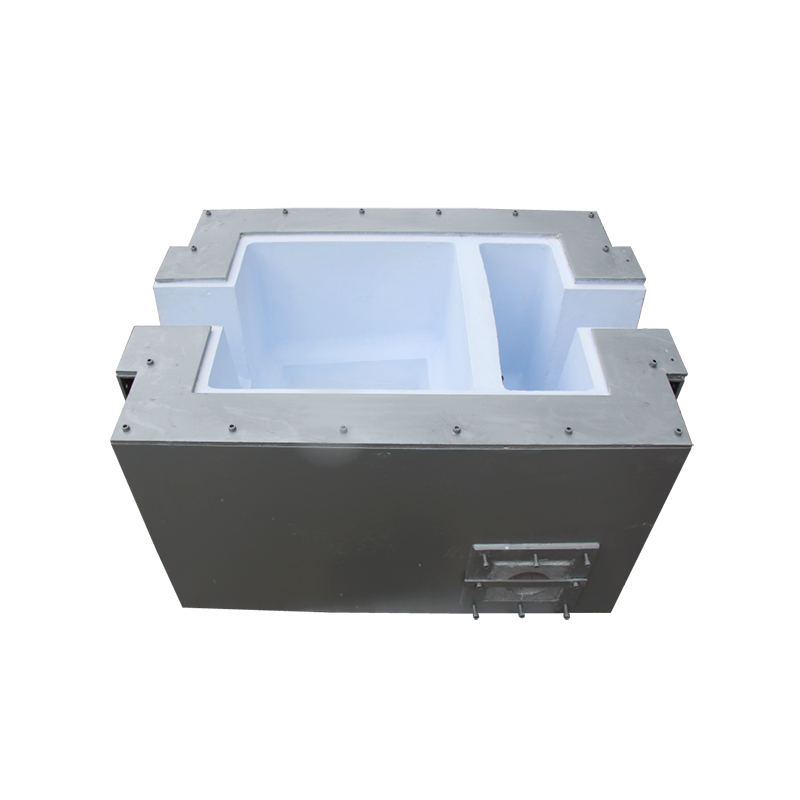

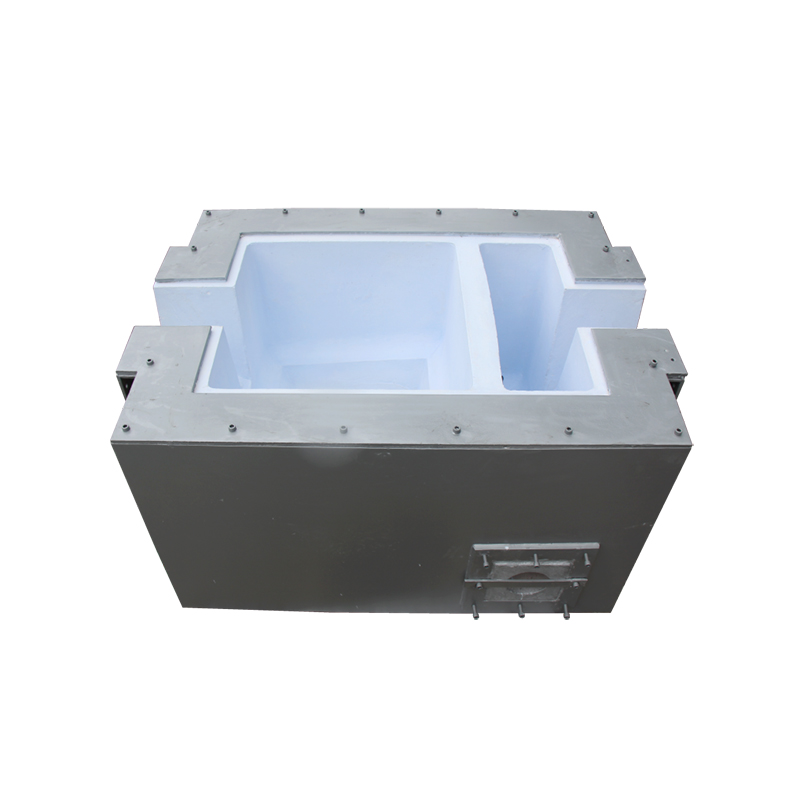

filter box with ceramic filter board filtering molten aluminum

The graphite plate at the exit of the aluminum extrusion press plays a lubricating role. Generally, more coarse-grained graphite is used. The high-purity graphite is fine and smooth, and the probability of scratching the aluminum material is very small. Using this high-purity material will greatly increase the service life and save costs relatively.

Product name: Aluminium profile graphite sheet

Product attributes: customized processing Specializing in the production of various graphite products, which can be customized according to customer needs!

1.If you have drawings, please send drawings (CAD, PDF, hand-drawn sketches).

2.Explain the size, quantity, thickness, etc.

3.Determine the processing technology (simple cutting, punching, custom-made heterosexual parts, grinding, milling and saw cutting, etc.).

4.Payment can be made after quotation.

Note: If the size is required to be particularly accurate, please explain, because there will be a certain tolerance for normal processes such as cutting, grinding and punching. If there are precision requirements for special-shaped parts, it should also be explained in advance. Mind shooting carefully Features: 1 Good temperature resistance 2 Lubrication and wear resistance 3 Good thermal conductivity 4 Professional custom precision machining

Suitable for casting applications with reticulated ceramic foam filtration.

1. It can be used directly at room temperature without worrying about thermal shock.

2. No thermal expansion and low thermal conductivity.

3. It can float in aluminum, reducing the possibility of refractory inclusions.

1. Clean the filter box.

2. Gently put the filter plate into the filter box, and press the sealing gasket around the filter plate by hand to prevent the flow of molten aluminum.

3. Preheat the filter box and filter plate evenly to make them close to the temperature of the molten aluminum. Preheat to remove moisture and facilitate initial instant filtration. Preheating can be carried out using electric or gas heating. Under normal circumstances, it takes about 15--30 minutes.

4. Pay attention to the change of the aluminum hydraulic head when casting. The normal initial pressure head is 100-150mm. When the molten aluminum begins to pass, the pressure head will drop below 75--100mm, and then the pressure head will gradually increase.

5. During the normal filtration process, avoid knocking and vibrating the filter plate. At the same time, the launder should be filled with aluminum water to avoid too much disturbance of the aluminum water.

6. After the filtration, take out the filter plate in time and clean the filter box.

Forming size standard, providing reliable support for effectively realizing the filtration efficiency of the foam ceramic filter plate. In addition to general specifications, it can be designed and manufactured according to customer needs.