Aluminium Tube Extrusion - Factory, Suppliers, Manufacturers from China

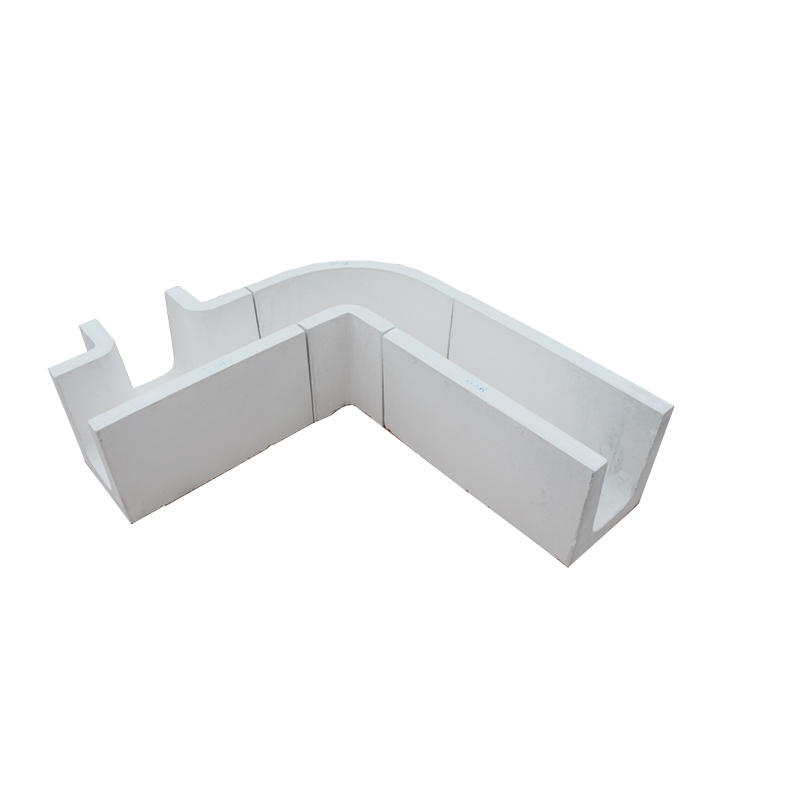

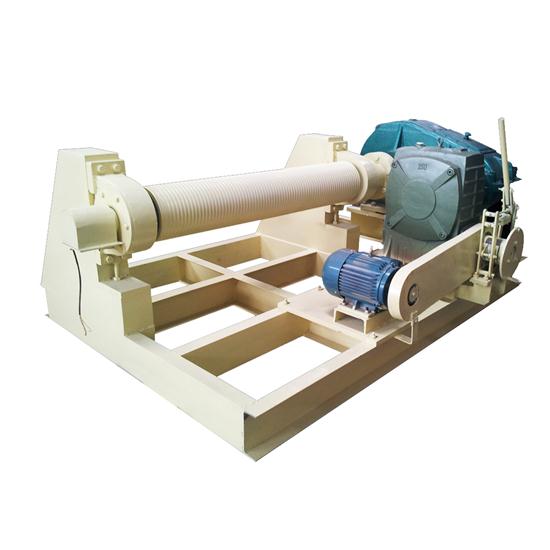

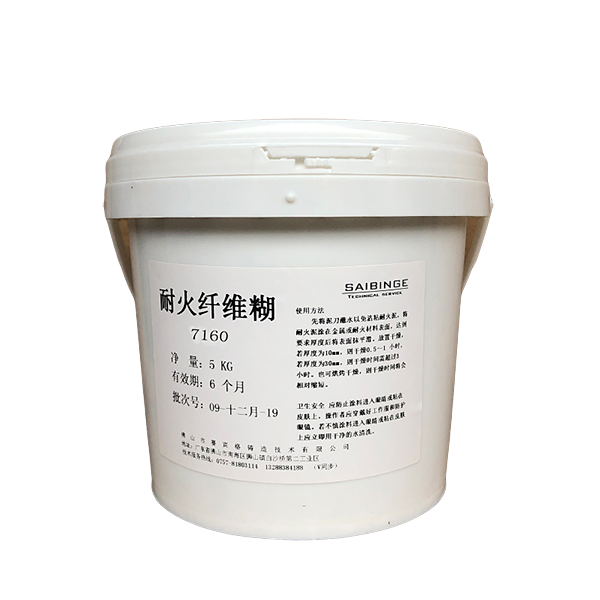

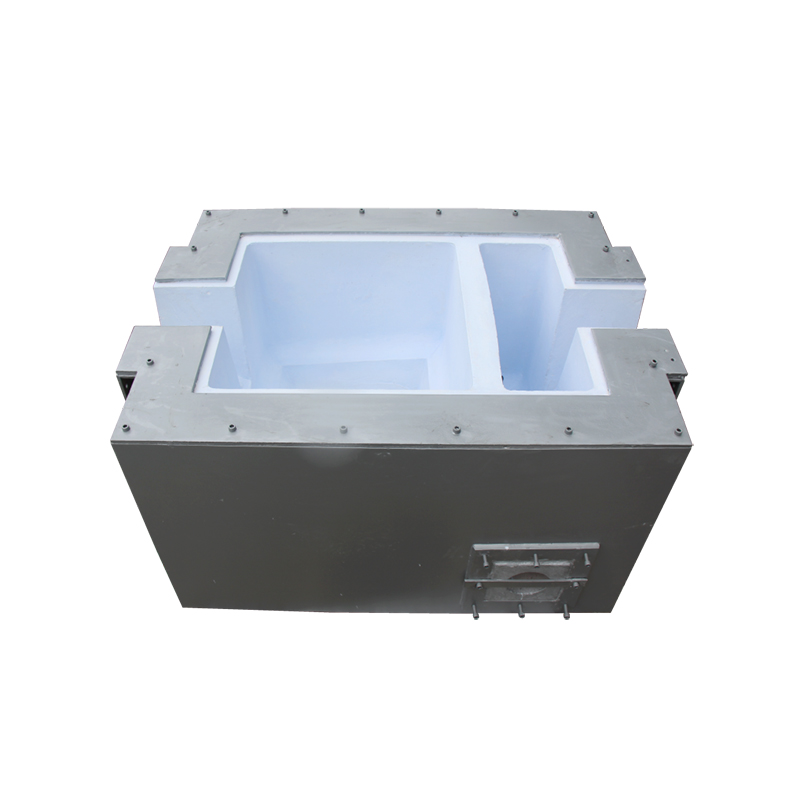

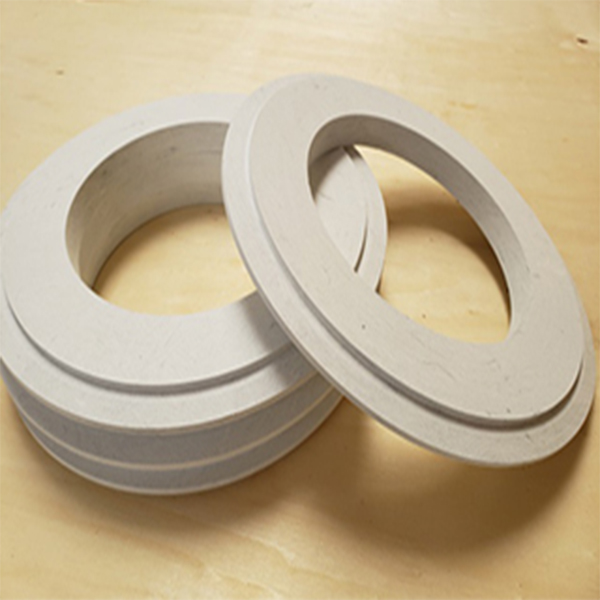

We have a minimum capacity of 500KG medium frequency furnace, electric furnace, etc. for aluminum plants with small output, and there are also fixed large-scale aluminum melting roads with a capacity of 5UST to 88UST, for aluminum casting plants with larger output. Aluminium Tube Extrusion, Aluminium Extrusion Heat Sink, Sn&Ni Salt Electrolytic Coloring Additive, Furnace Blocks,Metal Silicon. Extrusion process: The Billets are to be heated and cut to short before entering the extrusion press machine Extrusion ram push the short aluminum billet into container and through the extrusion die. Then aluminum profile comes out, and pulled by the puller tractor, conveyed on cooling table,heated by aging furnace. Finally through surface treatment such as powder coating or anodizing, the aluminum profile product is finished. The product will supply to all over the world, such as Europe, America, Australia,Turin, United Arab Emirates,Cologne, Paris.Aluminum extrusion molding (or aluminum extrusion) is a plastic working method that applies strong pressure to the aluminum billet placed in the mold cavity (or extrusion cylinder), forcing the aluminum billet to produce directional plastic deformation and extrude from the die hole of the extrusion mold, so as to obtain the required cross-sectional shape, size and certain mechanical properties of the parts or semi-finished products.

Related Products