The aluminum casting process is inseparable from various accessories. These accessories play an important role in cast aluminum alloy products.

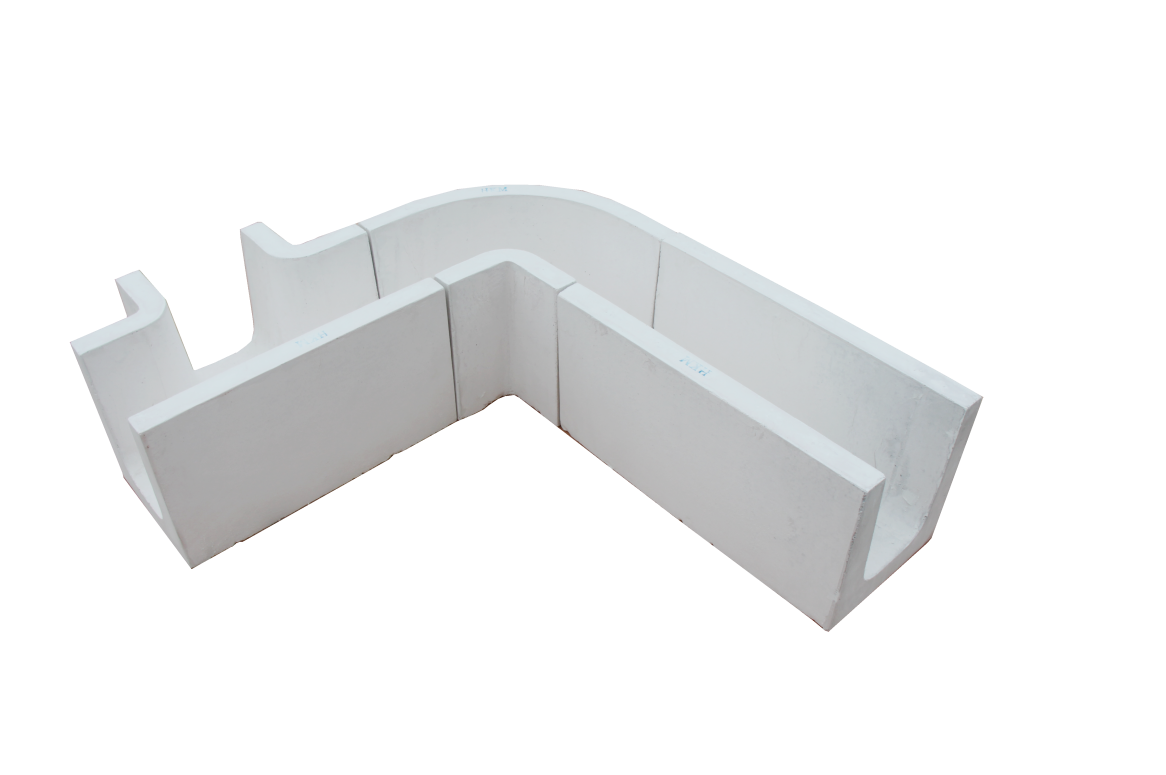

The first is the ceramic launder, which is an important tool for transporting molten aluminum from the furnace to the casting mold. It is designed to ensure an even and controlled distribution of molten aluminum, preventing any imbalance or variation during the casting process. It is designed to withstand high temperatures and ensure efficient transfer of liquid aluminum without any contamination. This is critical to maintaining the quality and integrity of the final aluminum alloy product. The design of the ceramic launder allows for a smooth flow of molten aluminum, preventing any blockages or interruptions in the flow.

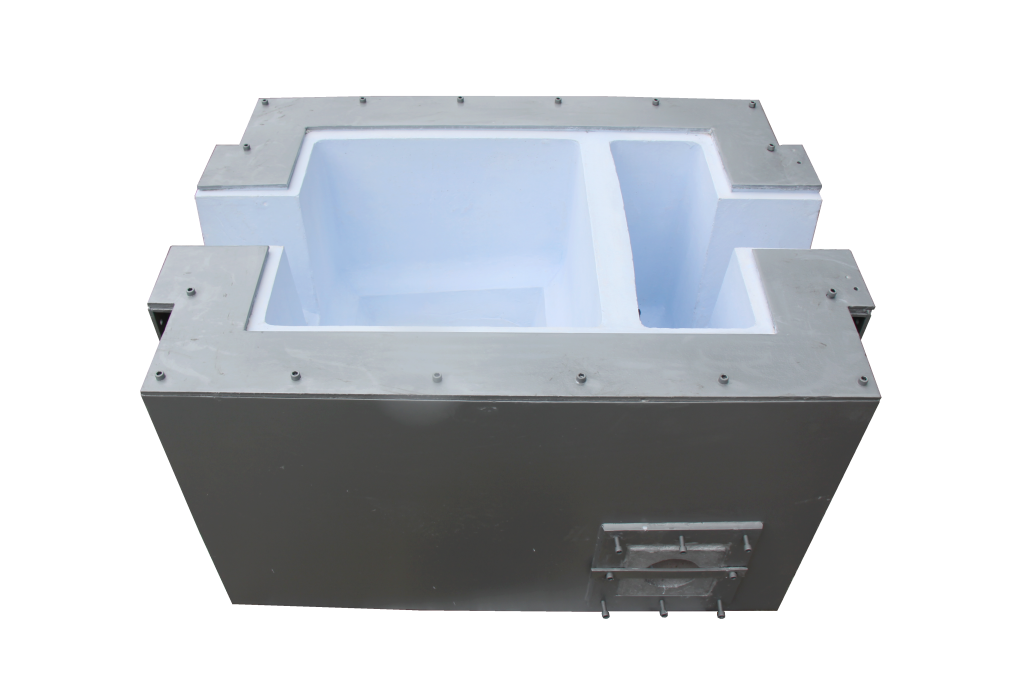

The filter box is an accessory specially designed to accommodate ceramic foam filters, which are composed of special ceramic fibers and inorganic ceramic materials. When using ceramic foam filter to filter aluminum and aluminum alloy melts, it is a necessary accessory to form a stable filter cavity. It has good thermal shock resistance, high strength, strong mechanical impact resistance and low thermal conductivity. The main purpose of the ceramic foam filter is to remove impurities in the aluminum liquid. By effectively absorbing aluminum slag, it can significantly reduce the possible pollution of the aluminum liquid during the casting process. This plays an important role in the quality of the final aluminum product.

The other is the distribution launder, which is a key component located on the top of the casting mold. The distribution launder is responsible for distributing molten aluminum to multiple molds at the same time. This is important to improve process efficiency and increase casting productivity. Its function can funnel the purified aluminum liquid into the casting mold. This ensures an even distribution of the aluminum liquid, eliminating any possibility of uneven filling or defects in the final product.

As molten aluminum flows into the casting mold, it begins transformation into aluminum billets. This is where the crystallizer comes into play. Crystallizers has excellent thermal conductivity and can withstand high temperatures. The main function of the crystallizer is to promote the solidification process, allowing the aluminum liquid to cool and form the desired shape. The crystallizer is an important accessory to ensure the correct shaping of the aluminum billet. If it fails, not only will the aluminum liquid fail to condense into aluminum billets, but there is also a risk of explosion. At this time, another important accessory is needed, a stoppter cone of aluminum silicate to stop the penetration of liquid aluminum and avoid major accidents.

These are indispensable accessories in the hot top casting process. Each accessory has its unique function. These aluminum accessories improve the efficiency and quality of the aluminum casting process: Ceramic foam filter ensure the removal of impurities and protect the molten aluminum from potential contaminants. While the shunts ensure even distribution throughout the mold. Finally, the crystallizer controls the solidification process, converting the liquid aluminum into a high-quality aluminum billet. To sum up, the aluminum casting process requires the use of various accessories to ensure the production of high-quality aluminum alloy products. Ceramic launders, crystallizers, distribution launders and filter boxes are all important tools that contribute to the success of the casting process. These accessories not only increase the efficiency and productivity of the process, but also produce high-quality, defect-free aluminum castings.

Post time: Oct-07-2023