In the aluminum foundry industry, the use of aluminum ceramic launder to convey molten aluminum is critical to ensuring a smooth and efficient production process. A well-designed and well-operated ceramic launder can greatly improve the metallurgical quality of a casting and contribute to energy-saving.

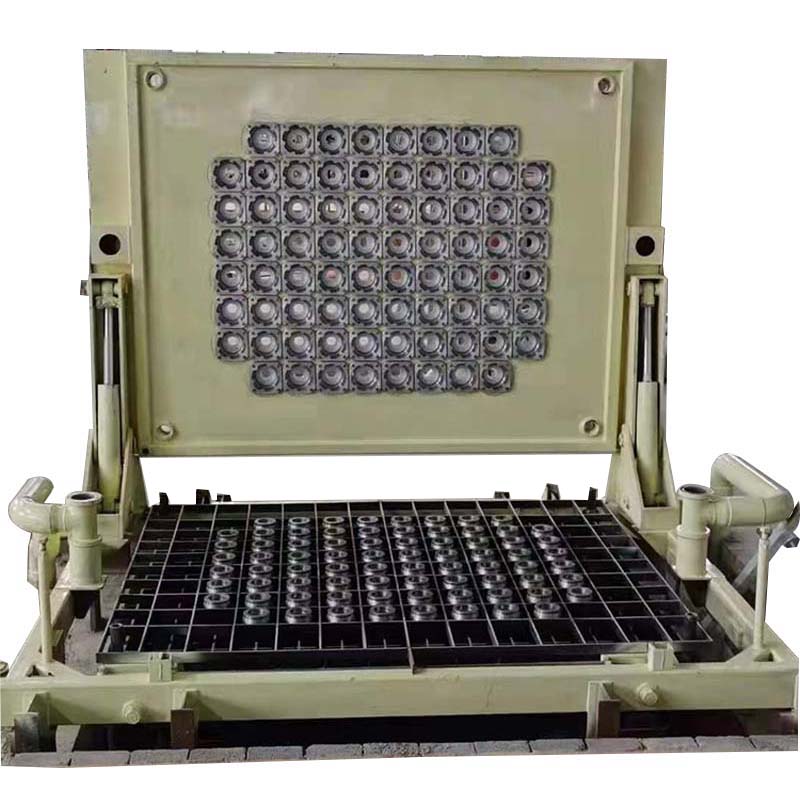

An aluminum ceramic launder is a channel used to convey molten aluminum from a furnace to a casting mold. It plays a vital role in maintaining the integrity of the liquid aluminum and ensuring it reaches the mold. The design and construction of the ceramic launder is critical to achieving these goals.

One of the main benefits of using an aluminum ceramic launder in the casting process its ability to lower the temperature of the molten aluminum. By directing the liquid through well-insulated and properly lined launders, the temperature can be better controlled, preventing overheating. This is especially important for producing high-quality castings with the desired properties.

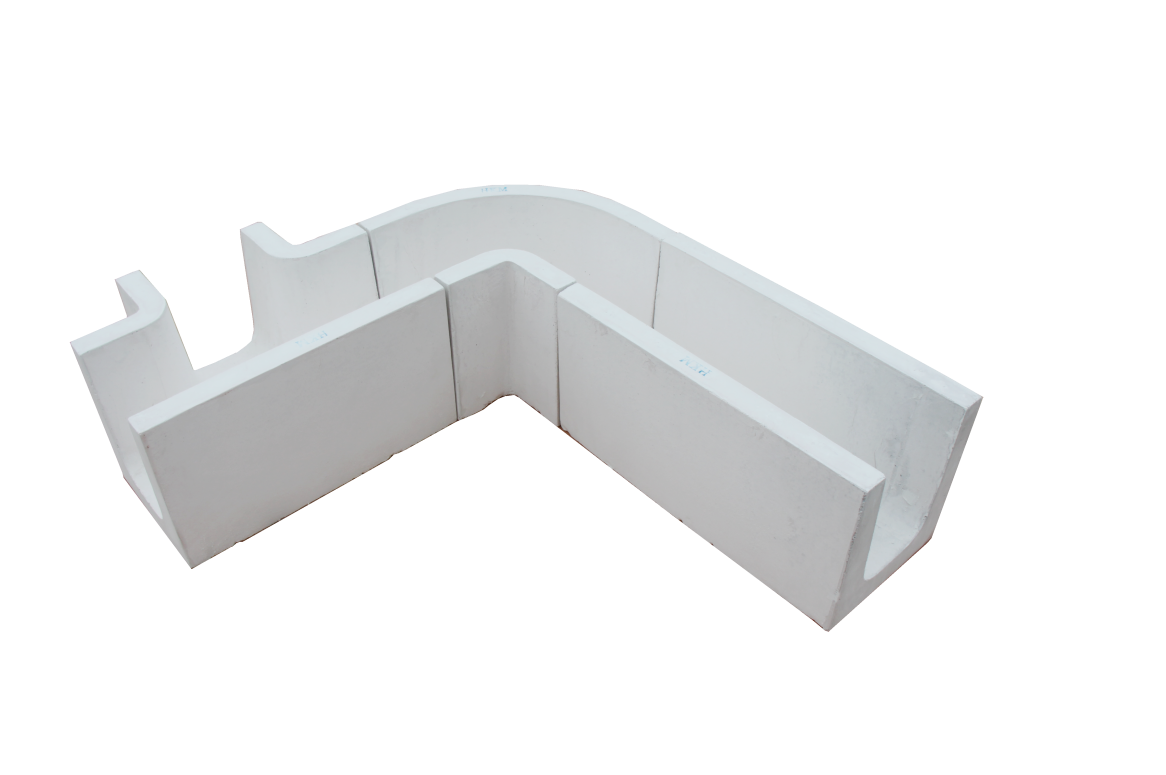

Beyond these basic functions, aluminum ceramic launders come in a variety of shapes to suit different foundry setups and requirements. Whether the flow groove has various shapes such as DC groove, elbow, tee, cross and so on, the shape of the ceramic launder can be cu

stomized to meet the specific needs of the casting process. In addition, the lining of the launder is designed to have a smooth surface, which is not only conducive to the smooth flow of molten aluminum, but also contributes to its thermal shock resistance. This is critical as temperature unstable can cause cracks and damage to the launder.

Another important property of aluminum ceramic launder is their long service life. The lining material used is selected for its durability and ability to withstand the harsh conditions of the foundry environment. This ensures long-term efficient operation of the launder, reducing downtime and maintenance costs.

In addition, the lining material of the aluminum ceramic launder is specially formulated to not stick to aluminum. This means that the molten aluminum does not stick to the liner, this non-stick property also helps improving the quality of casting. In the hot top casting process,

a thin layer of talcum powder should be spread on the launder before casting, there should be no exposed iron pieces and the channel through which the molten aluminum passes should be kept clean and dry, allowing for a smooth, continuous flow.

In summary, the use of an aluminum ceramic launder in the aluminum casting process is essential for conveying molten aluminum. It not only improves the metallurgical quality of castings, but also contributes to energy saving. The ability to reduce the temperature of molten aluminium, protect the alloying elements are key advantages of using aluminum ceramic launder. By using advanced materials with high strength, corrosion resistance and thermal shock resistance, the ceramic launder ensures a long service life and minimizes downtime. With its non-stick properties, the ceramic launder also helps prevent contamination and ensures the production of high-quality castings.

Post time: Aug-16-2023