Aluminum drossing flux is a specialized product used in the aluminum industry to solve the dross during the aluminum melting processes. Dross is a byproduct that forms on the surface of molten aluminum due to oxidation and the inclusions. The main function of aluminum drossing flux is to improve metal quality, and enhance the efficiency of the aluminum production. Here are the primary functions and applications of aluminum drossing flux.

The function of aluminum drossing flux is to remove and separate the dross from the molten aluminum. The drossing flux contains chemical agents that can react with the dross, forming a layer material that helps to agglomerate the aluminum slag, making it easier to remove the dross from the molten aluminum. The drossing flux can help separating the slag in the aluminum and make it reacts with metallic impurities, helping to agglomerate. It also used for frying residue with waste heat.This process contributes to the overall purity and quality of the final aluminum product.

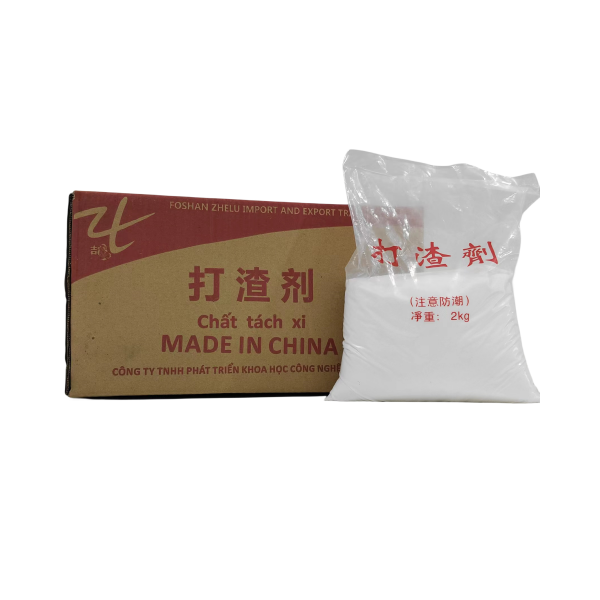

In the application aspect, aluminum drossing flux is typically used in various types of melting furnaces, such as melting furnaces, crucible furnaces. It’s added to remove of dross during the melting process.In the process of dealing with aluminum slag, the worker just need to throw some drossing flux into the furnace, then strring and add the flux according the temperature till the slag and aluminum separate.

Aluminum drossing flux is an essential tool in the aluminum industry for controling dross formation, improving metal quality, and enhancing the efficiency of the production process. By facilitating dross removal, preventing oxidation, the use of aluminum drossing flux contributes to producing high-quality aluminum products for different industries. The appropriate selection and application of drossing flux are crucial to achieving optimal results and minimizing waste.

Post time: Jul-22-2023