Welcome to our websites!

Factory Price Aluminum Holding Furnace - Continuous Casting Machine for aluminum alloy ingot – ZheLu

Factory Price Aluminum Holding Furnace - Continuous Casting Machine for aluminum alloy ingot – ZheLu Detail:

Product detail pictures:

Related Product Guide:

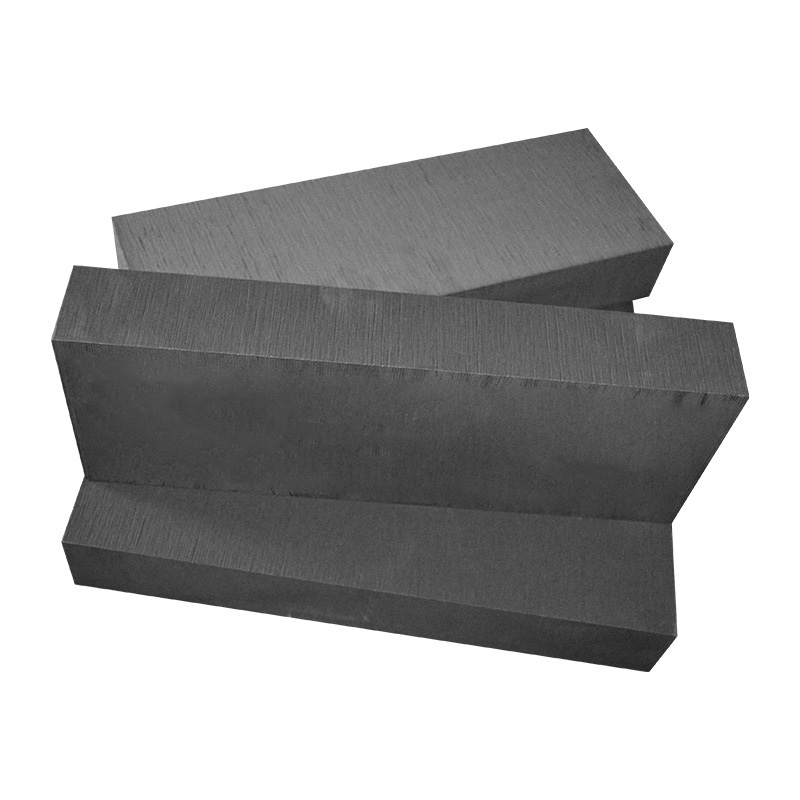

We can fully provide all the materials and accessories used in the production of aluminum ingot production and aluminum rod, including aluminum melting furnace equipment, launder, filter box, online degassing equipment, hot top casting, aluminum ingot casting production line, stacking ingot robot, dust removal equipment, ash stir-frying machine, ball mill, etc., out of the casting industry, the post-processing link of aluminum rod - aluminum profile extrusion, we can also provide products. Aluminum extruder, single rod heating furnace or multi-rod heating furnace, mold heating furnace, mold nitriding furnace, hydraulic oil cooler, cold bed, straightening machine, traction machine, online quenching, aging furnace, air compressor and other equipment, as well as graphite plate, mold, high temperature drum, ring belt, felt sleeve and other consumable materials. Factory Price Aluminum Holding Furnace - Continuous Casting Machine for aluminum alloy ingot – ZheLu , The product will supply to all over the world, such as: Romania, Algeria, Hyderabad, Aluminum extrusion molding (or aluminum extrusion) is a plastic working method that applies strong pressure to the aluminum billet placed in the mold cavity (or extrusion cylinder), forcing the aluminum billet to produce directional plastic deformation and extrude from the die hole of the extrusion mold, so as to obtain the required cross-sectional shape, size and certain mechanical properties of the parts or semi-finished products.

This supplier's raw material quality is stable and reliable, has always been in accordance with the requirements of our company to provide the goods that quality meet our requirements.